What is the Bonna Pipe RCCP?

Mr Aimé Bonna was a French Engineer and entrepreneur that invented the Reinforced Concrete steel Cylinder Pipe (RCCP) in 1894.

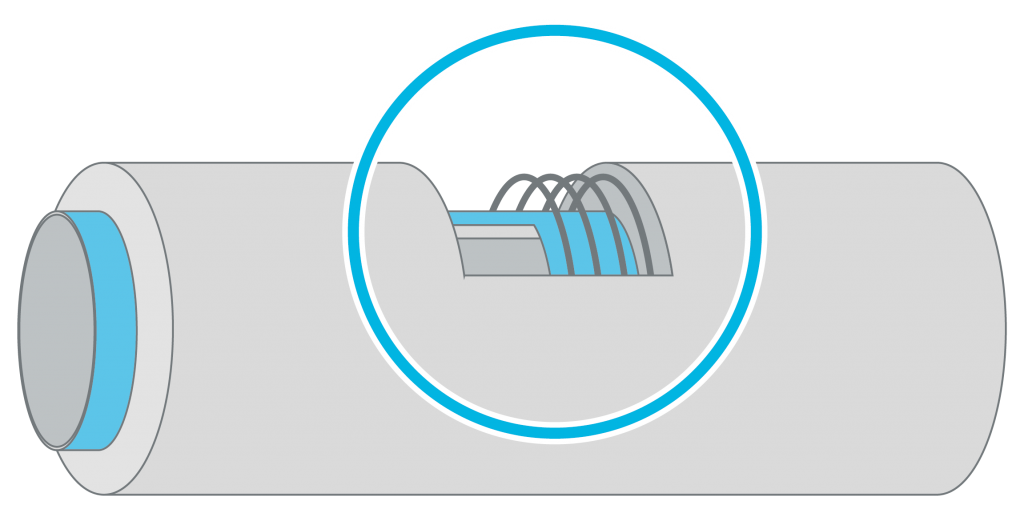

Mr Aimé Bonna was a French Engineer and entrepreneur that invented the Reinforced Concrete steel Cylinder Pipe (RCCP) in 1894. The Bonna Pipe RCCP as a concrete pipe with an embedded steel cylinder is composed of:

- A steel core made of rolled steel plates welded lengthwise or helically with welded end-rings

- A steel reinforcement cage made by helical winding of a steel wire at a constant pitch

- An inner and outer concrete wall casted in one single operation highly vibrated and compacted

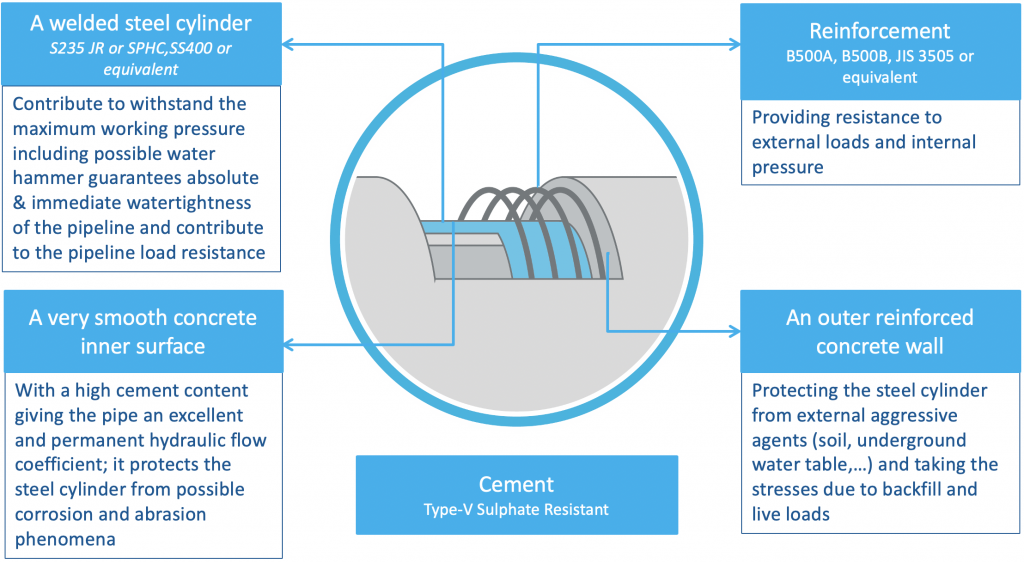

Optimized Materials for the Bonna Pipe RCCP

The Bonna Pipe RCCP design results from the optimum combination of steel and concrete characteristics & performances. PT. Bonna Indonesia implemented EN-639/EN-641 Standards equivalent to AWWA C300.

"Bonna Pipe RCCP is the proven pipe material with over 120 years of experiences and references worldwide!"

Dimensional Characteristics of the RCCP

The Bonna Pipe RCCP starts from 300 mm to 4000 mm nominal diameter.

| Nominal Diameter (mm) | 600 | 800 | 900 | 1000 | 1100 | 1200 | 1400 | 1500 |

| External Diameter (mm) | 840 | 970 | 1050 | 1164 | 1276 | 1390 | 1640 | 1740 |

| SL ends Effective Length (m) | 6.15 | 6.15 | 6.15 | 6.15 | 3.00 | 6.15 | 6.15 | 6.15 |

| Weight per Meter (t) | 0.69 | 0.61 | 0.64 | 0.73 | 0.85 | 1.00 | 1.48 | 1.58 |

| Nominal Diameter (mm) | 1600 | 1800 | 2000 | 2100 | 2200 | 2400 | 2500 | 2600 |

| External Diameter (mm) | 1880 | 2100 | 2320 | 2440 | 2560 | 2800 | 2910 | 3030 |

| SL ends Effective Length (m) | 6.15 | 6.15 | 6.00 | 6.00 | 4.50 | 5.03 | 4.50 | 2.91 |

| Weight per Meter (t) | 1.95 | 2.44 | 2.87 | 3.18 | 3.50 | 4.22 | 4.48 | 4.87 |

| Nominal Diameter (mm) | 2800 | 3000 | 3200 | 3400 | 3500 | 3600 | 3800 | 4000 |

| External Diameter (mm) | 3280 | 3480 | 3720 | 3980 | 4080 | 4200 | 4450 | 4640 |

| SL ends Effective Length (m) | 3.50 | 3.00 | 2.91 | 2.63 | 2.41 | 2.32 | 2.12 | 2.03 |

| Weight per Meter (t) | 5.83 | 6.20 | 7.18 | 8.46 | 8.68 | 9.21 | 10.15 | 10.80 |

Table caption elements

Figures in blue and bold show existing moulds and equipment at Bonna Indonesia factory.

Figures in green and bold show ordered moulds and equipment not yet available at Bonna Indonesia factory.

Figures in pink or diameters not mentioned show no moulds and equipment at Bonna Indonesia factory.

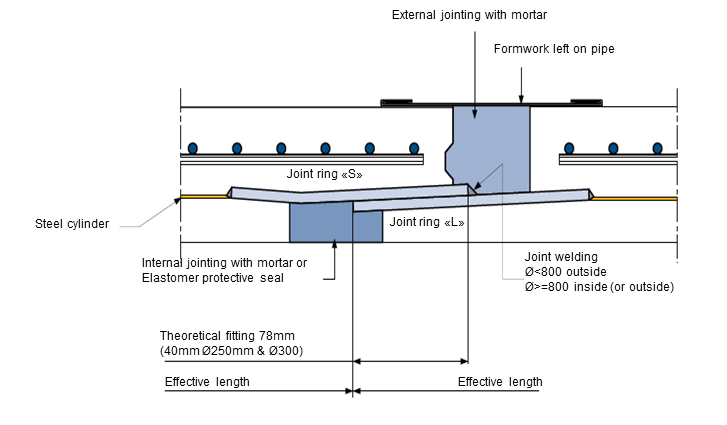

Bonna Pipe RCCP Joint Connection

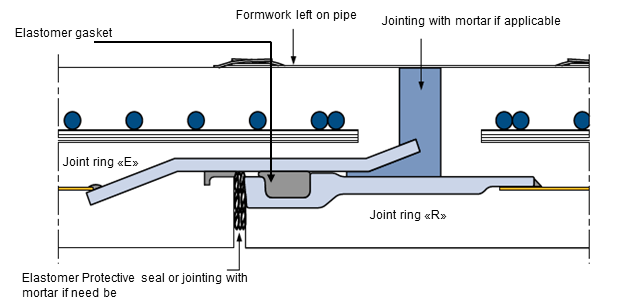

Bonna Conical SL Thrust-Restrained Joint: Welded Joint

Bonna ER Flexible Joint: Spigot Joint

Low Head Loss

Bonna Design Office uses the Colebrook-White Formula for hydraulic calculation with roughness coefficient of k=0.0001 m that corresponds to the internal lining of the Bonna pipelines cast in rigid metallic moulds or poured with spin process.

This "k" represents our products characteristics, as delivered, factory made, and laid in accordance with our technical notices.

Experience has shown that, for pipelines with an internal cement-based lining applied according to modern techniques, it is appropriate to take k = 0.0001 m.

This coefficient for k merely reflects a hydraulic behaviour that has been observed and quantified empirically. Some generic studies are available and private test, performed on achieved project, confirm this assessments.

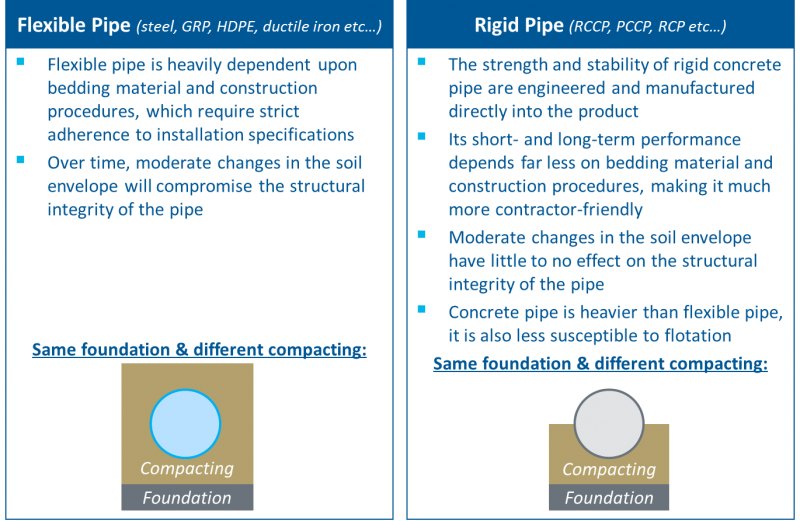

Understand the Difference between Flexible and Rigid Pipe